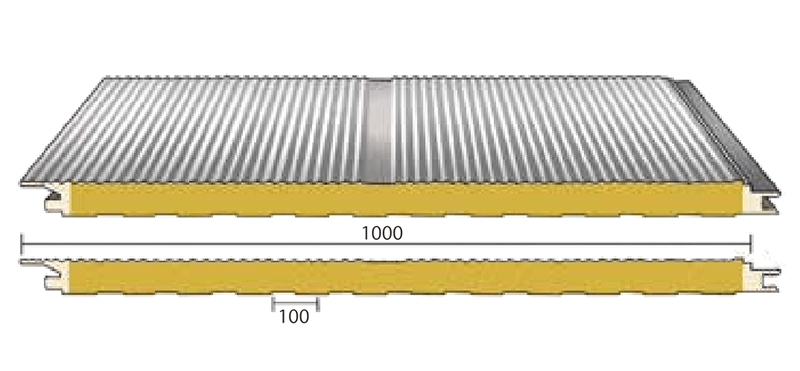

SMALL RIPPLE

Integrating three-dimensional sense and elegant decorative effect, the gloss, chroma and brightness of the wall produce bright and dark stripes with different light angles and positions.

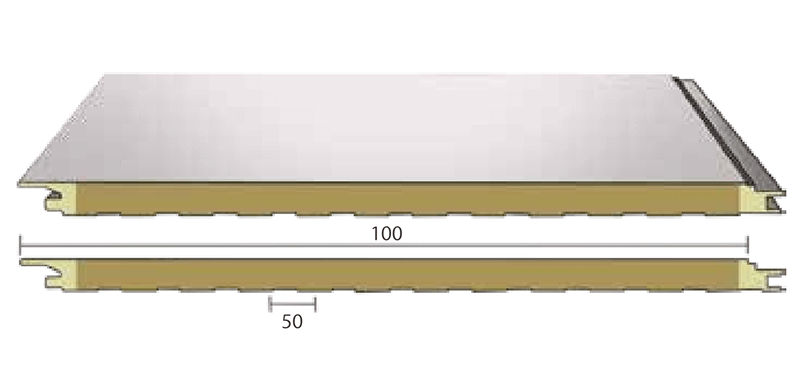

MIDDLE GROOVE

The groove design in the middle of the board shape allows the 1000 mm wide wall panel to show two 500 mm visual effects, and is equipped with elegant small ripples, making the building more layered and textured.

PURE FLAT

A model of purity and elegance, the gloss, chroma, and brightness of the wall produce unique visual changes with different light angles and positions.

PERFORMANCE DESCRIPTION

PARAMETERS TO DESCRIBE | |||

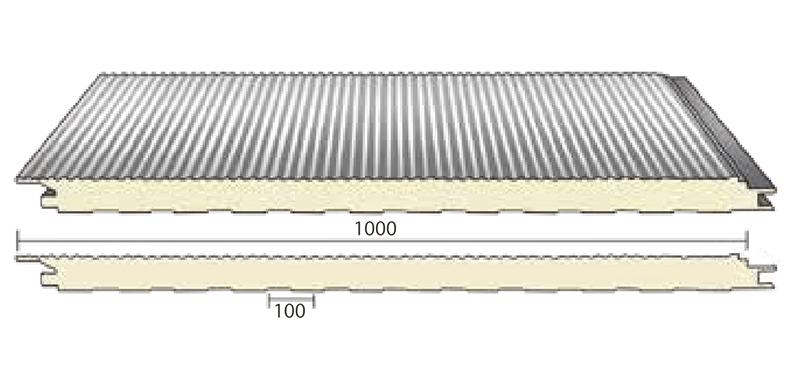

Sheet name | The wall panel | ||

Effective cover | 400-1000mm | ||

Steel thickness | 0.4-0.7 | ||

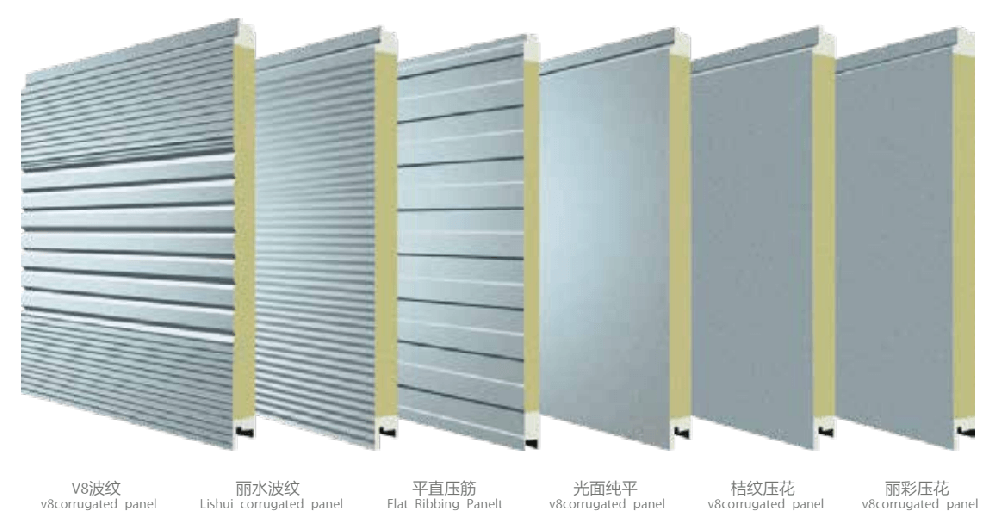

表面花纹 | Small ripple, medium groove, plain | ||

On the surface of decorative pattern | White grey, silver, sea blue, etc | ||

Recommend coating | Fluorocarbon coating PVDF, SMP coating, HDP coating, polyester PE coating, etc | ||

The thickness of the core material | 50、75、100, etc | ||

The name of the core material | Polyurethane (pu) | Polyurethane edge sealing fiberglass wool | Polyurethane edge sealing rock wool |

Coefficient of thermal conductivity | 0.019-0.024w/m.k | 0.035-0.041w/m·k | 0.037-0.043w/m·k |

HEAT TRANSFER COEFFICIENT

The whole thickness | K value (K/㎡h℃) | Heavy plate | The load distribution | ||||||||||||

Simply supported(mm) | continuous(mm) | ||||||||||||||

P=kg/㎡ | 60 | 80 | 100 | 120 | 150 | 200 | 60 | 80 | 100 | 120 | 150 | 200 | |||

50 | 0.80 | 15.13 | L= | 4207 | 3665 | 3254 | 2942 | 2581 | 2148 | 4711 | 4093 | 3644 | 3295 | 2890 | 2405 |

75 | 0.53 | 17.94 | L= | 5609 | 4894 | 4373 | 3969 | 3500 | 2936 | 6282 | 5481 | 4897 | 4445 | 3920 | 3288 |

100 | 0.41 | 20.75 | L= | 6840 | 5977 | 5349 | 4862 | 4296 | 3612 | 7660 | 6694 | 5990 | 5445 | 4811 | 4047 |

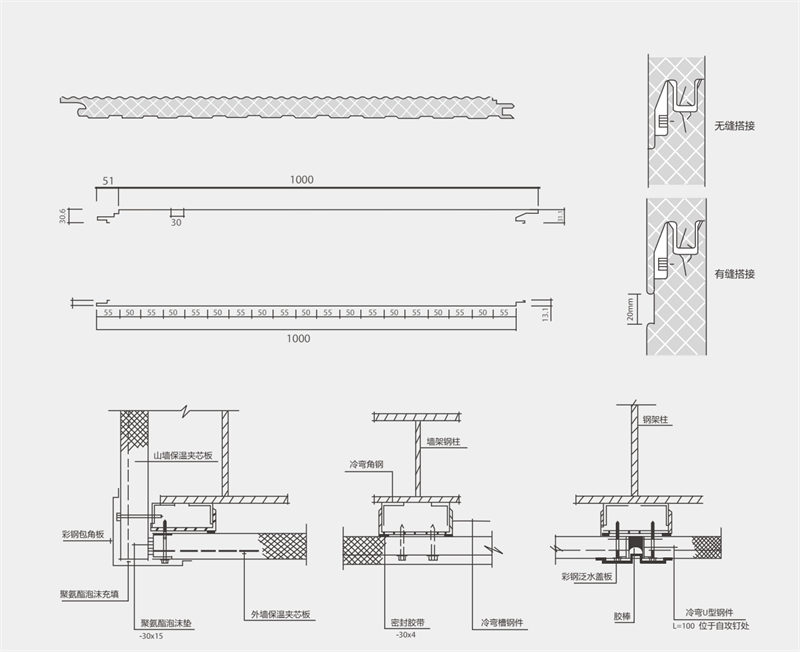

DIVERSE SIDE EFFECTS ARE OPTIONAL

HEAT TRANSFER COEFFICIENT

The whole thickness | K value (K/㎡h℃) | Heavy plate | The load distribution | ||||||||||||

Simply supported(mm) | continuous(mm) | ||||||||||||||

P=kg/㎡ | 60 | 80 | 100 | 120 | 150 | 200 | 60 | 80 | 100 | 120 | 150 | 200 | |||

45 | 0.43 | 11.18 | L= | 3956 | 3445 | 3072 | 2784 | 2448 | 2046 | 4430 | 3858 | 3440 | 3118 | 2741 | 2291 |

50 | 0.39 | 11.38 | L= | 4268 | 3721 | 3323 | 3014 | 2655 | 2224 | 4780 | 4167 | 3721 | 3375 | 2973 | 2490 |

60 | 0.33 | 11.78 | L= | 4861 | 4246 | 3800 | 3453 | 3049 | 2564 | 5444 | 4755 | 4256 | 3867 | 3414 | 2871 |

75 | 0.26 | 12.38 | L= | 5688 | 4980 | 4464 | 4064 | 3599 | 3038 | 6370 | 5577 | 4999 | 4551 | 4030 | 3402 |

100 | 0.20 | 13.38 | L= | 6941 | 6087 | 5466 | 4984 | 4423 | 3746 | 7773 | 6817 | 6121 | 5582 | 4953 | 4195 |

120 | 0.16 | 14.18 | L= | 7853 | 6890 | 6189 | 5645 | 5013 | 4250 | 8795 | 7716 | 6931 | 6322 | 5614 | 4760 |

150 | 0.13 | 15.38 | L= | 9099 | 7980 | 7166 | 6534 | 5800 | 4913 | 10190 | 8937 | 8025 | 7318 | 6496 | 5502 |

Note: The values in the table above are taken from the outer plate 0.6mm, the inner plate 0.5mm, and the polyurethane capacity 40kg/m³

EN

EN